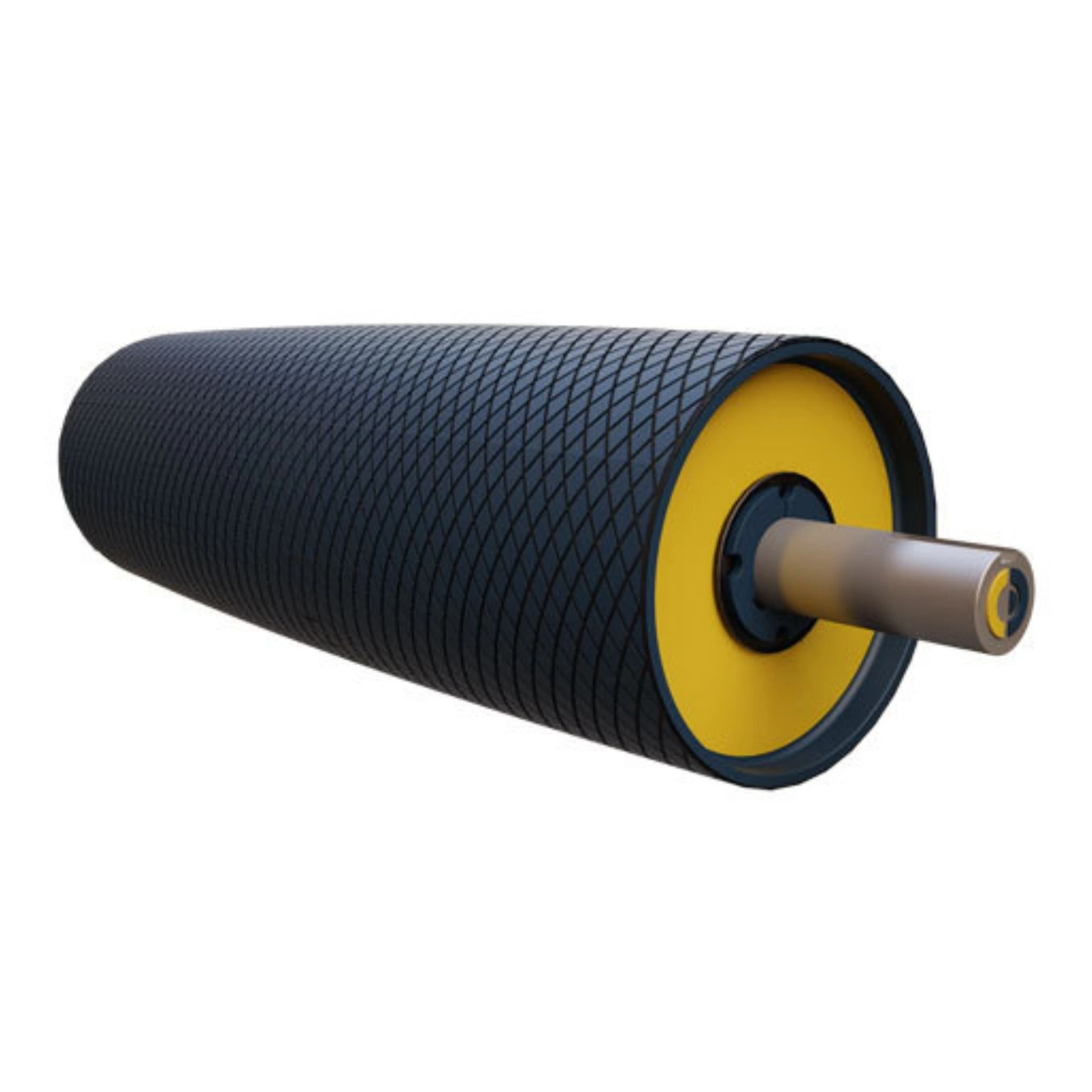

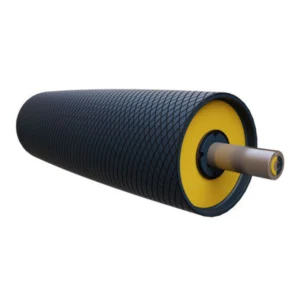

Drum Lagging is the process of applying a rubber or ceramic layer to the surface of conveyor drum pulleys to increase friction, prevent belt slippage, and reduce wear. This coating enhances the performance of conveyor systems by improving belt tracking and reducing downtime due to maintenance. Drum lagging is widely used in mining, cement plants, and bulk material handling industries where conveyor systems are integral to operations. Available in various materials and patterns, drum lagging can be customized to meet specific operational requirements.

Key Features:

- Improves friction and reduces belt slippage.

- Extends the lifespan of conveyor belts and pulleys.

- Available in rubber or ceramic materials for added durability.

- Customizable designs to meet specific industry needs.

Related Products

Clients

We proudly serve some of the world’s leading companies, trusted by top-tier clients globally for our exceptional products.

arrows

arrows

العربية

العربية 简体中文

简体中文 Nederlands

Nederlands English

English Français

Français Deutsch

Deutsch Italiano

Italiano Português

Português Русский

Русский Español

Español