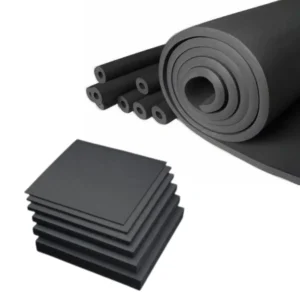

Cold Lining

Cold Lining is a specialized application of protective linings for industrial tanks, vessels, and pipes, designed to protect surfaces from corrosion and chemical exposure without the use of high-temperature curing.

Cold Lining is a protective coating solution applied to the interior of tanks, vessels, pipes, and other equipment in industrial settings to prevent corrosion and chemical damage. Unlike hot lining processes that require heat to cure, cold lining involves applying linings at ambient temperatures, making it an efficient and cost-effective option for sensitive environments. This method is ideal for chemical plants, power plants, and industries where heat-sensitive materials are stored or processed.

Key Features:

- No heat curing required, making it suitable for sensitive environments.

- Protects against corrosion, chemical exposure, and abrasion.

- Suitable for tanks, vessels, and pipes.

- Cost-effective solution for extending the life of equipment.

Related Products

Clients

We proudly serve some of the world’s leading companies, trusted by top-tier clients globally for our exceptional products.